The steering rack needs to be removed and dismantled for crack testing.

The rack is mounted directly onto the front bulkhead. The aluminum and steel plates from under the radiator and behind the radiator to funnel hot air out on either side have been removed in the above photo as have the brake and clutch master cylinders, all of which tend to clutter this area up significantly.

Steering arms are steel tubes with welded in threaded ferrules at the end instead of the more usual aluminium components used on many other cars of the period.

Fairly standard design 10.5 inch diameter three spoke steering wheel.

Steering wheel is mounted a long way back from the dash, which would suit a shorter driver. Being tall I will need the wheel to be closer to the dash and I will also fit a quick release mechanism for the wheel. In order to do this I will make a new steering rod and keep the existing for posterity (or use by a future shorter owner / driver), and perhaps just in case Niki Lauda wanted to take the car for a spin when it is restored!

The steering rack is very long, a full 24 inches.

Steering wheel height is adjustable by some 3.5 inches all up, there are 6 positions, three with the mounting block facing down (as per the above photo) and another three higher positions if the mounting block is unbolted and rotated upside down.

Steering rack is attached to the chassis via bolt plates inside the monocoque side pods.

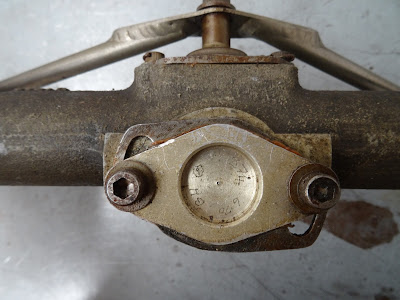

Access to the pinion drive peg is via removal of this fitting which through it being an eccentric machining allows adjustment of the pinion to rack height.

This end plate also houses a roller bearing. This is a bit unusual as generally on most race cars the pinion runs inside bronze bushes.

Pinion as removed from the rack. It also has three positions for mounting the end of the steering column enabling a small amount of on track fore and aft adjustment of the steering wheel before needing to change the column.

The other end of the pinion is also supported by a roller bearing.

Further dismantling to remove the toothed rack from inside the cast rack requires manufacture of some special tools, which Crawford Hall is now undertaking.